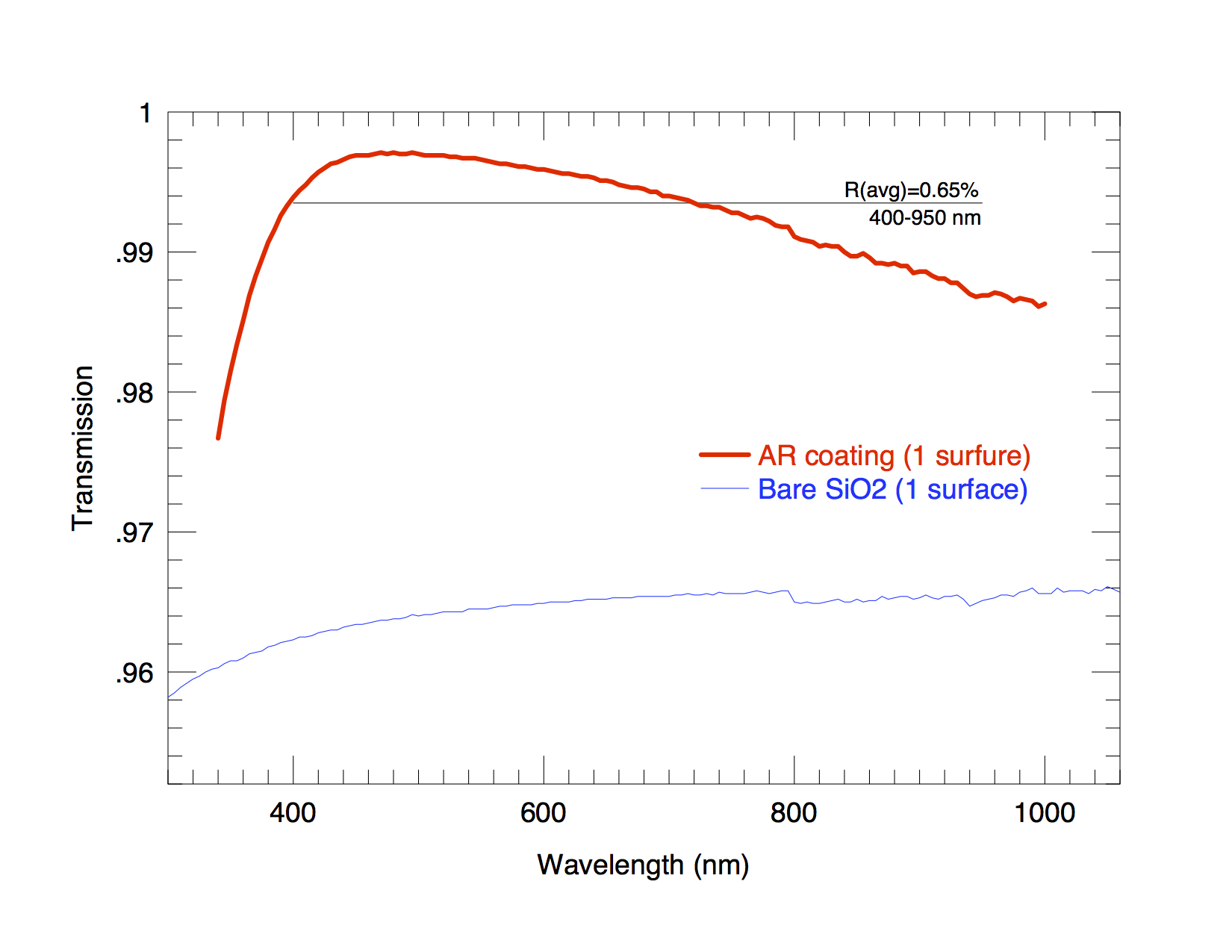

Anti-Reflection (AR) Coatings

The AR coatings we have dealt with to date are all based on silica sol-gel.

Silica sol-gel is essentially nanospheres of silica suspended in a solvent, typically ethanol. It can be applied by a number of relatively low-tech methods: spin-coating, dip-coating and meniscus coating (the last for flat surfaces only). In spin coating, the substrate is placed on a turn-table and rotated at high speed. Sol-gel is added to the center of the substrate, and centrifugal force throws most of it off immediately. The remaining film is kept at uniform thickness because of surface tension, but it continues to thin because fluid is lost at the edges. At some point, a combination of this thinning plus evaporation of the solvents causes the coating to "freeze", leaving a uniform layer of the silica nanospheres. This coating is extremely fragile, so a final step is to place it into a chamber with moist ammonia, which fuses the nanosphere together while retaining the porous structure -- we call this processes "hardening".

The resulting silica layer is very porous with a refractive index ideal for AR coatings on most glass, producing almost perfect transmission at one particular wavelength. Our work has been to broaden the "pass-band" (the range of wavelengths) over which sol-gel based coatings would be effective. This is achieved by combining it with additional layers of materials, particularly MgF2, which are applied in our PVD chamber. These additional layers serve to broaden the passband, while sligthly reducing the peak performance. Since sol-gel does not adher well to MgF2, we add a thin "bond layer" of Al2O3 overtop the MgF2, and then spin-coat with sol-gel.

The advantage of these sol-gel based coatings is that they can be applied to very large optics. As an example, we first started exploring sol-gel to coat two 1.1-m thin prisms for the Keck-I telescope. As the coating is made from just a few layers of increasing refractive index, another advantage is that the performance is not highly sensitive to thickness variation or broad ranges in incidence angle. The challenges are that the sol-gel process can be somewhat unstable, varying with environmental conditions when it is applied, and especially with amount of index change as the coating is hardened. Also, the coatings should be protected with a hydrophobic agent to avoid picking up moisture in the pores, which will reduce performance somewhat. We are working to resolve these issues. An additional continuing challenge is to keep the surfaces clean of dust while spin-coating to avoid cosmetic defects.

|

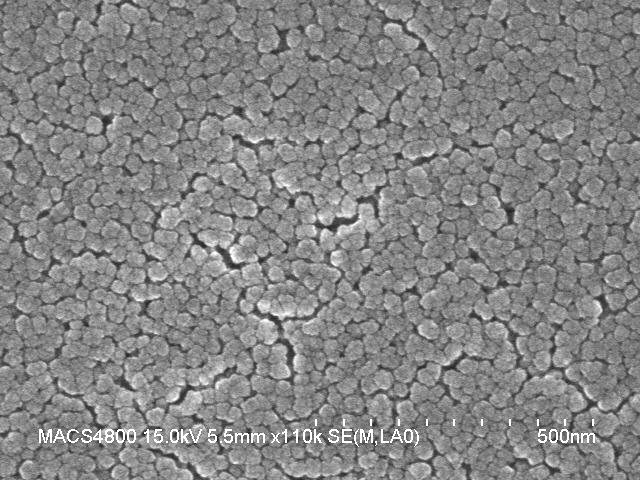

(left) This image, made with a Scanning Electron Microscope (SEM), shows the appearance of a fresh layer of sol-gel. The nanospheres are held together only by weak van der Waals forces, and are so weakly bonded that residual electrostatic charge from the SEM forced open a number of cracks while this image was acquired. The scale in microns is shown in the image. (SEM images courtesy of David Fryauf.) |

|

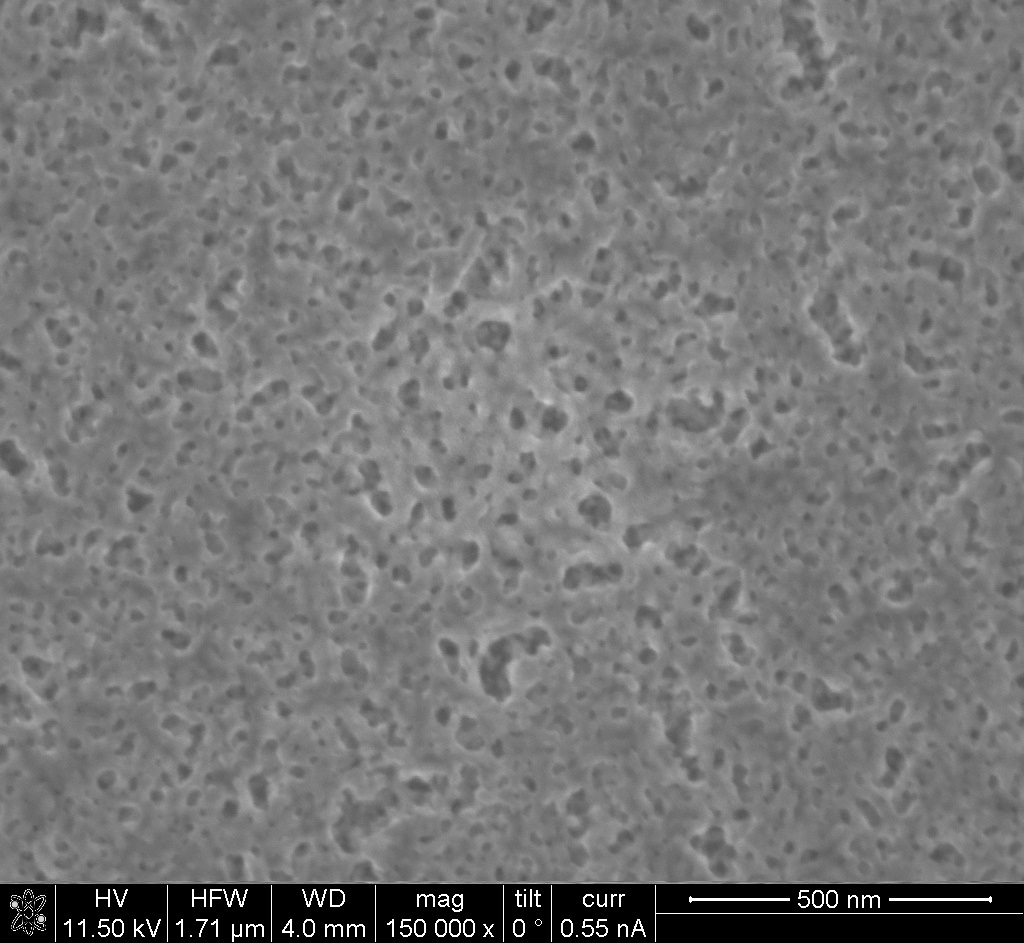

(left) Another SEM image (of similar scale) showing "hardened" sol-gel after the nanosphers are fused togther. While the material is much better bonded and connected, it retains most of its porous structure. It is the porosity that gives sol-gel its low refractive index. |

|

(left) As an example of large optics that need good AR-coatings, this is one of the Keck-I Atmospheric Dispersion Corrector prisms we coated with the hybrid coating in our lab. At this point, the prism had been coated with the PVD layers and was being transfered to a modified optical polishing tool we used as a turntable. The [carefully-balanced!] prism was rotated at 150 rpm during the spin-coating. |

The Advanced Coatings Lab has received National Science Foundation support via Award AST-1005506. NSF is not responsible for the content of this website.