Facilties

PVD Chamber

Our PVD vacuum chamber is a 48-inch diameter stainless steel tank originally built as a bake-out oven. The chamber has undergone continuous modifications and enhancements since about 2003, when it was first assembled as a coating chamber in our lab. It now contains a Temescal 6-pocket e-gun, Kaufmann and Robinson EH-2000 ion source, and three MSI 3-inch magnetrons for coating deposition. The vacuum system has a Leybold D65 pump with a Fomblin fluid for roughing (to about 30 mTorr) and a 16-inch CryoTorr cryopump with a VAT gate valve. Supporting equipment includes Inficon thickness monitors with IC-5 controller, vacuum gauges, and a Residual Gas Analyzer (RGA). Substrates are mounted at the top of the chamber facing downward, and are held on a single-axis rotating stage. The inside of the chamber is accessed by removing the large bell with an overhead crane.

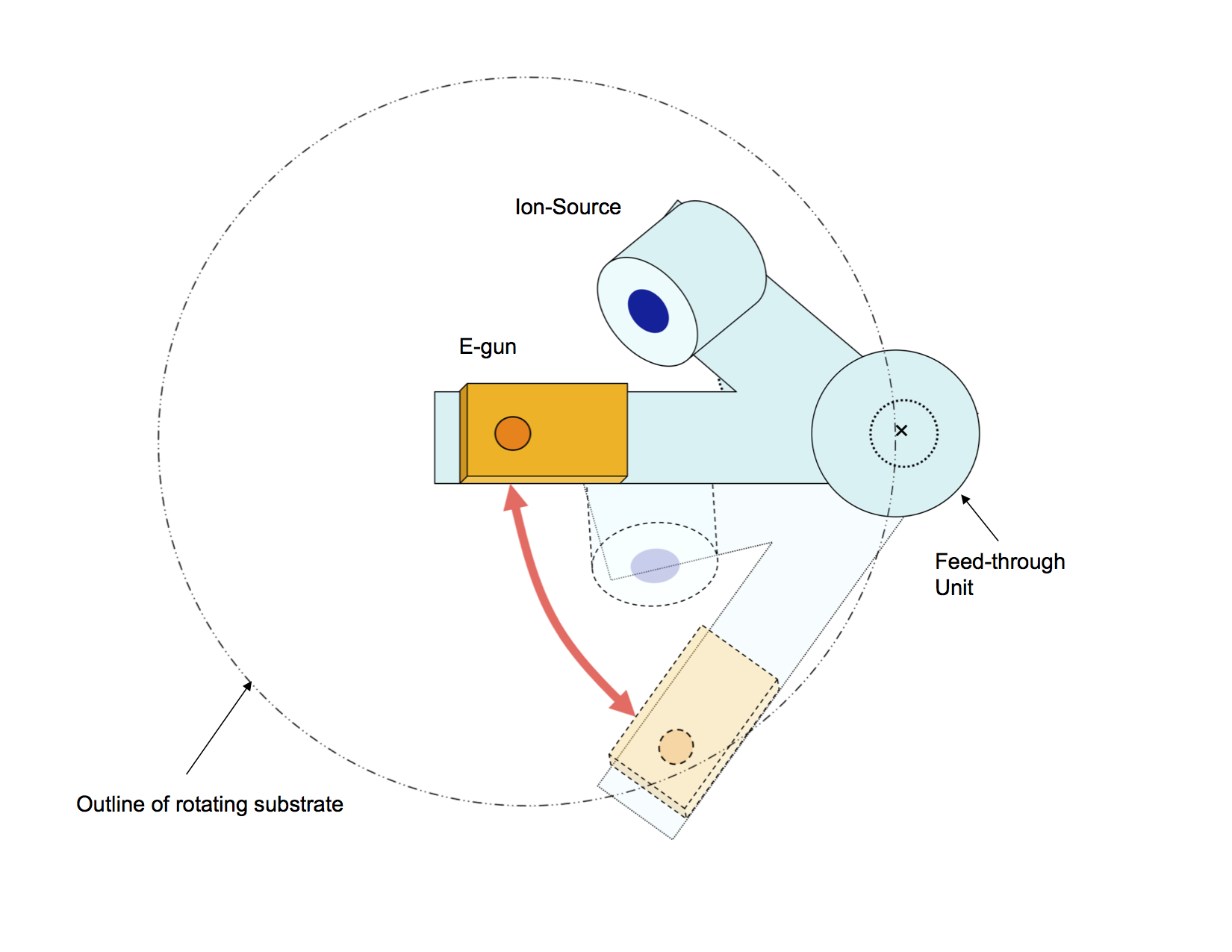

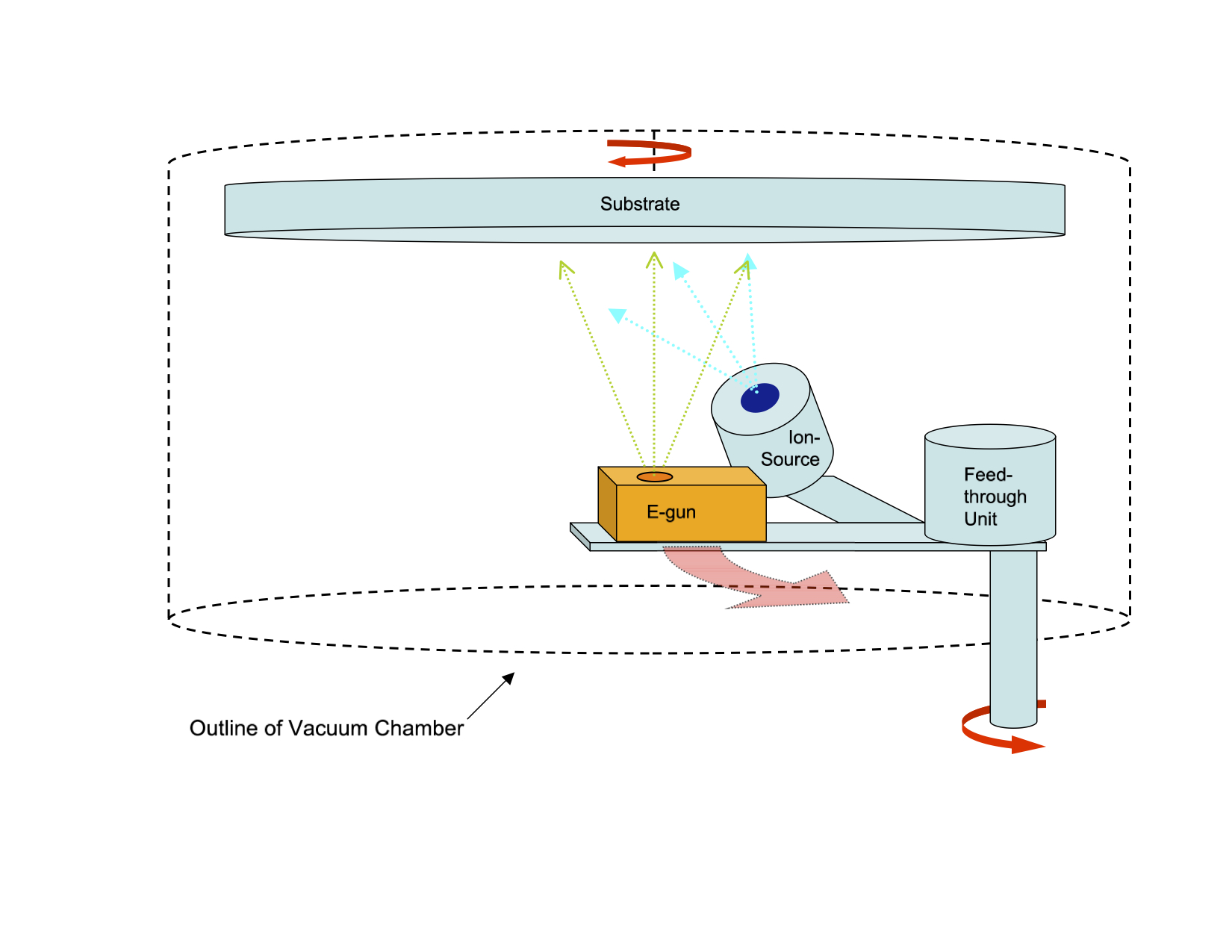

Our chamber is unique in that the deposition sources and ion source are mounted on "swing-arms" that move them from the center to near the edge of the chamber. The concept is illustrated in Fig. 1a,b:

Fig.1a: top view |

Fig.1b: side view |

No matter where the swingarm is positioned, the e-gun, ion source and substrate being coated have the same fixed geometry, so the film structure will be uniform. Moving the arm from center to edge allows good thickness uniformity also. This arrangement allows us to coat large optics with good uniformity, even though both the chamber and the deposition sources are relatively small.

This arrangement also has the advantage that all service lines (gases, cooling water, power) are fixed inside the vacuum, so that leaks, shorts, etc., are less likely to develop. All lines that must flex as the swingarm rotates are located at atmospheric pressure. The inside of the feedthrough unit is also at atmospheric pressure, and so we can use motors and other electronics within the feedthrough unit. Included in the feedthrough unit is a CCD camera that looks at the e-gun via a periscope, and because everything rotates as a unit, the view is fixed.

The latest phase of modifications, including purchase of most of the components above, was funded in large part by the National Science Foundation through Award AST-1005506, whose support we gratefully acknowledge.

|

(left) The PVD vacuum chamber, closed up for operation, with the electronics rack on the right. |

|

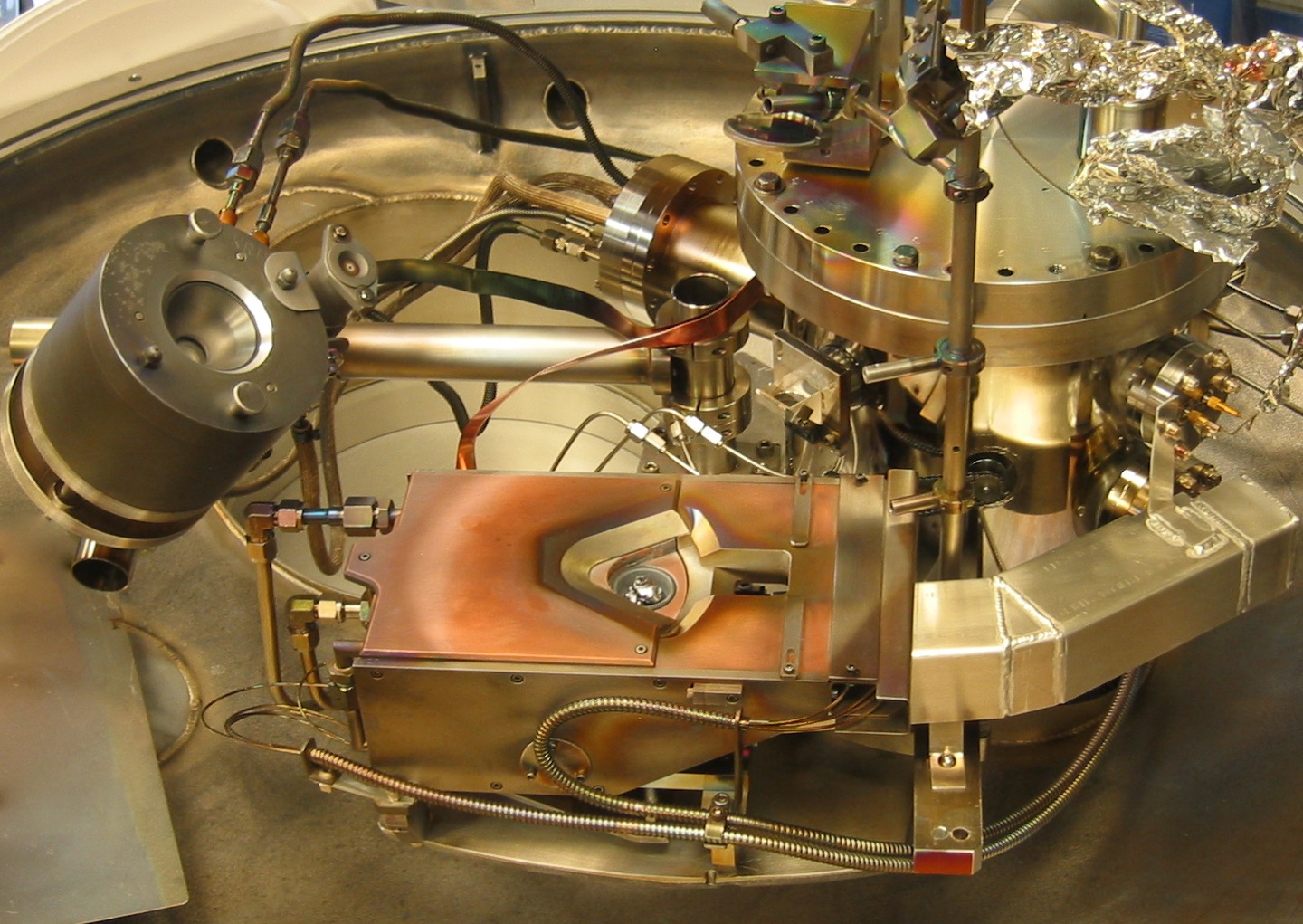

(left) The interior of the chamber showing the egun, ion source thickness monitors, feedthrough unit and periscope optics. (Photo taken before magnetrons were installed.) Mouse over to identify components. |

Measurement and Analysis

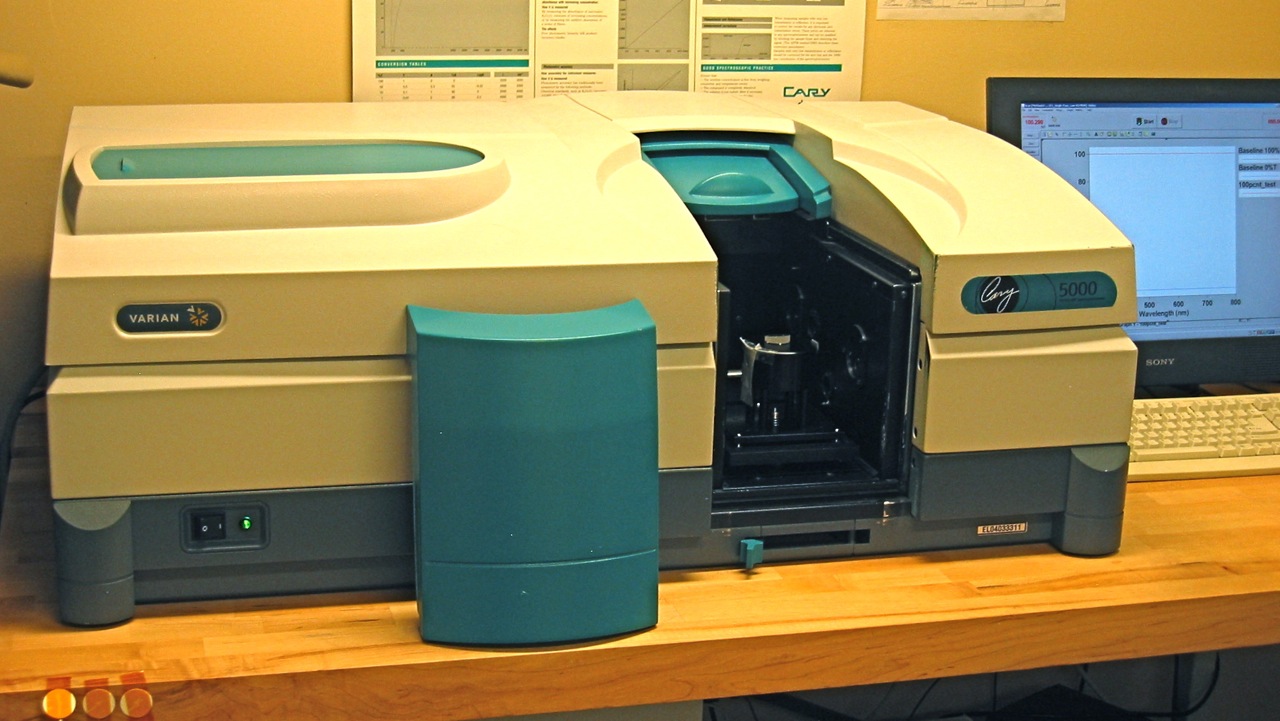

We use a Cary 5000i to measure reflectivity and/or transmissivity of our coatings samples over the wavelength range 200 nm to 3.3 microns. This is a dual-beam scanning monochromometer. We have accessories for normal angle transmission; absolute specular reflectivity near 7 degrees incidence; and relative specular reflectance at 8 degrees incidence. The latter accessory was purchased to measure very low reflectivity of AR coatings. We also use a StellarNet fiber-fed CCD spectrometer covering the range 200 nm to 1.1 microns. This instrument is less accurate, but allows us to make measurements on large optics, and to measure wavelengths of minima and maxima in single-layer sol-gel samples without removing them from the spin-coater.

|

(left) The Cary 5000i spectrophotometer. The sample compartment is open and the relative specular reflectance accessory is in place. |

The Advanced Coatings Lab has received National Science Foundation support via Award AST-1005506. NSF is not responsible for the content of this website.